Our customers

Customized to food producers, ingredients suppliers and equipment manufacturers

Our aim is to supply information to support employees in production, maintenance and quality assurance to prevent quality problems caused by mechanical defects or insufficient cleaning.

Let’s connect!

1995

Operational Since

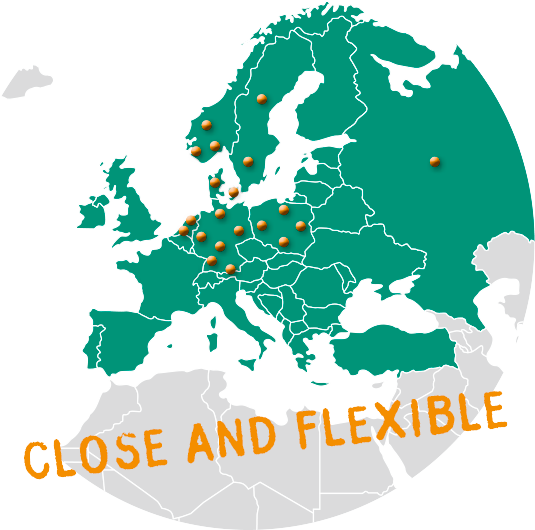

20+

Operational Countries

11.000+

Inspections in 2020

60

Employees in Europe

DAIRY

Production of all types of dairy products and powder ingredients

Click below to find typical examples of inspections.

+

BREWERY

From craft-beer to industry-scale beer production

Click below to find typical examples of inspections.

+

BEVERAGE

Production of carbonated drinks, juice, water, lemonade, spirits etc.

Click below to find typical examples of inspections.

+

INGREDIENTS

Production of powders, cultures, enzymes and natural ingredients

Click below to find typical examples of inspections.

+

MEAT

Production of meat products

Click below to find typical examples of inspections.

+

TANK PRODUCERS

Manufacturing of tanks and other equipment for the food industry

Click below to find typical examples of inspections.

+

FOOD

Production of salads, condiments, dressings, flavors, fine foods, etc.

Click below to find typical examples of inspections.

+

PHARMA

Production of pharmaceuticals and bio-tech products

Click below to find typical examples of inspections.

+

References

Working for global and local food producers

Facility knowledge

We can rely 100% on the inspectors. They really know their way around the facilities, bring the right equipment and work independent. It gives us the freedom to focus on our own tasks in the meantime.

– Dairy customer

Independent partner

We know that the report we receive is objective, because Bactoforce is independent. It is always better to collaborate with a partner that does not have a hidden agenda.

– Dairy customer

R-Force

Online access to reports, planning and risk management

R-Force is the on-line inspection management software, which allows our customers to have full access to inspection plans and reports at all times.

Use the system to exchange information with Bactoforce and stay in control with the hygienic condition of your production line.